Hyundai Reach Forklift Arlington

Reach Forklifts

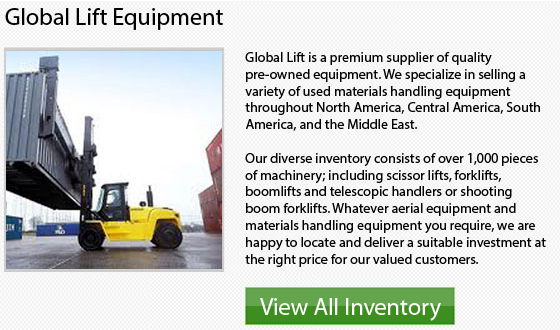

Space is usually at a premium in nearly all distribution centers or warehouse settings. The less space required for aisles in which to use machines, the more space overall you would have for the storage of goods and products. Thus, particular equipment has been designed for operating in very narrow aisles in order to maximize space and efficiency.

Reach Trucks

The specific reach lift truck has a mast which extends away from the forklifts body. Usually, it is attached with a scissor apparatus. When the scissor is drawn in or compacted, the forklift becomes a lot narrower compared to the typical forklift.

Operator Position

The majority of reach trucks are designed so that the driver is standing while operating the unit. This is a contrast to the regular lift truck where the operator is usually sitting. The standing operation area lessens the amount of room needed for the compartment of the driver, enabling the machinery to achieve an even smaller profile overall.

Space Saving

With a reach truck, aisles can be made as narrow as 7 feet. Most regular lift trucks require a minimum aisle space of about 11 feet; therefore, using a reach truck gives around a savings of 5 feet on each aisle. When the warehouse is leased by the square foot basis, this is a large amount of space.

Unique Controls

Usually, a reach truck is steered utilizing a rotating lever situated beside the driver on a platform. There is one more lever utilized to control reverse and forward, the mast and for extending the mast. These controls are quite different compared to standard forklift controls.

Load Capacity

Usually, the reach truck's load capacity is less than that of a standard lift truck, depending on the kind. This is largely because of the machine's narrow design, which could cause a really high center of gravity. When the mast is fully extended and the load is lifted, this is particularly true.

- MEC Scissor Lifts Arlington

Safety Requirements for Scissor Lifts Scissor lift machinery are known as "moveable scaffolds," according to the OSHA. These industrial machines are capable of lifting heavy and large loads that are balanced well. They are responsible... More - Doosan Dual Fuel Forklifts Arlington

Basic Training Information for LPG Liquid petroleum gas or LPG is a odorless and colorless fuel derived from natural gas. LPG consists of 90% propane. It is extracted in a process referred to as distilling.... More - Nissan Counterbalance Forklifts Arlington

Counterbalance lift trucks are essentially forklifts that are designed with counterweight at the back of the machine. The counterweight works to balance the weight which the tines are carrying at the front of the cargo.... More - Taylor Reach Stackers Arlington

TS Series Reach Stackers Taylor has set a new standard with their newest reach stacker container handlers. Their newest TS-9972 Reach Stacker is a user friendly, really comfortable and durable machinery. The TS-9972 has all... More - Komatsu Warehouse Forklifts Arlington

Warehouse Forklift Maintenance Having a proper maintenance program for forklifts would help to increase the lifespan of the equipment and is also a critical factor to the safe use of the equipment. Completing regular forklift... More